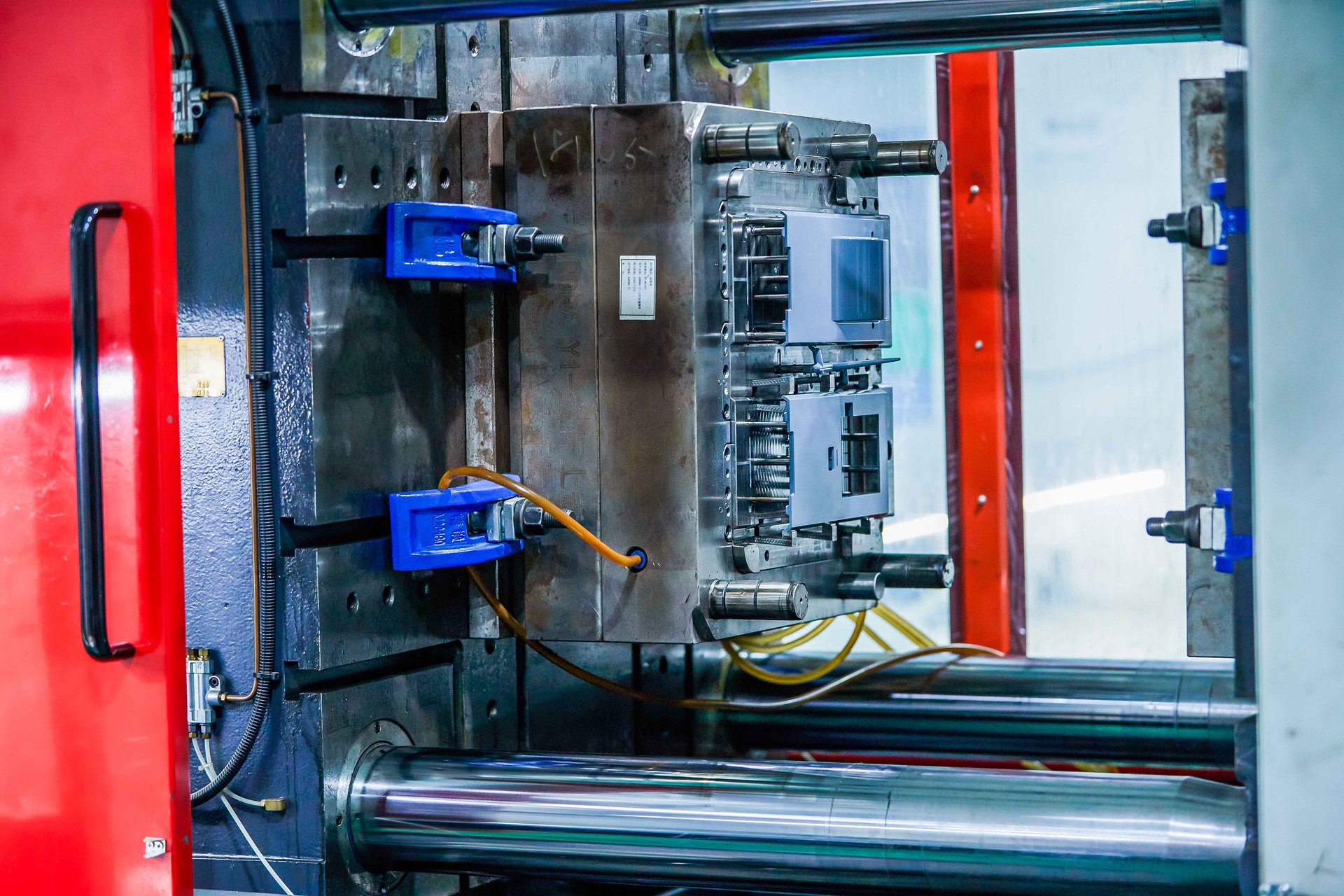

Plastic mold, is the important tool that makes the plastic products with a complete configuration and precise size.One of the most important factors of plastic mold that is capable of manufacturing millions of part, is the mold design. At the beginning of mold project, it requires the evaluation of design feasibility, process and equipment and other related matters. For example, whether the product shape and tolerance requirements can meet customer requirements, whether the existing internal processes can be satisfied, whether new processes need to be developed.

Of course, if we can involve the projects at the beginning of design, it will be much helpful for both Rex and the customers. The goal at Rex’s customized molds includes all services from prototype to parts ready to market. Most members of the mold team have at least 10 years of mold building experience, their dedicated experience combined with the latest technology, allows us to utilize the latest software to produce accurate molds manufacturing precise parts and helps to create profitability to our customer.

Main Services

• Design or optimize your product - We will work with you from design stage or provide optimized suggestion when prototype verification.

• Building mold - we can design and build the mold according to your design. If you don’t have any files but with samples, we also can do reverse engineering design to get and verify the files.

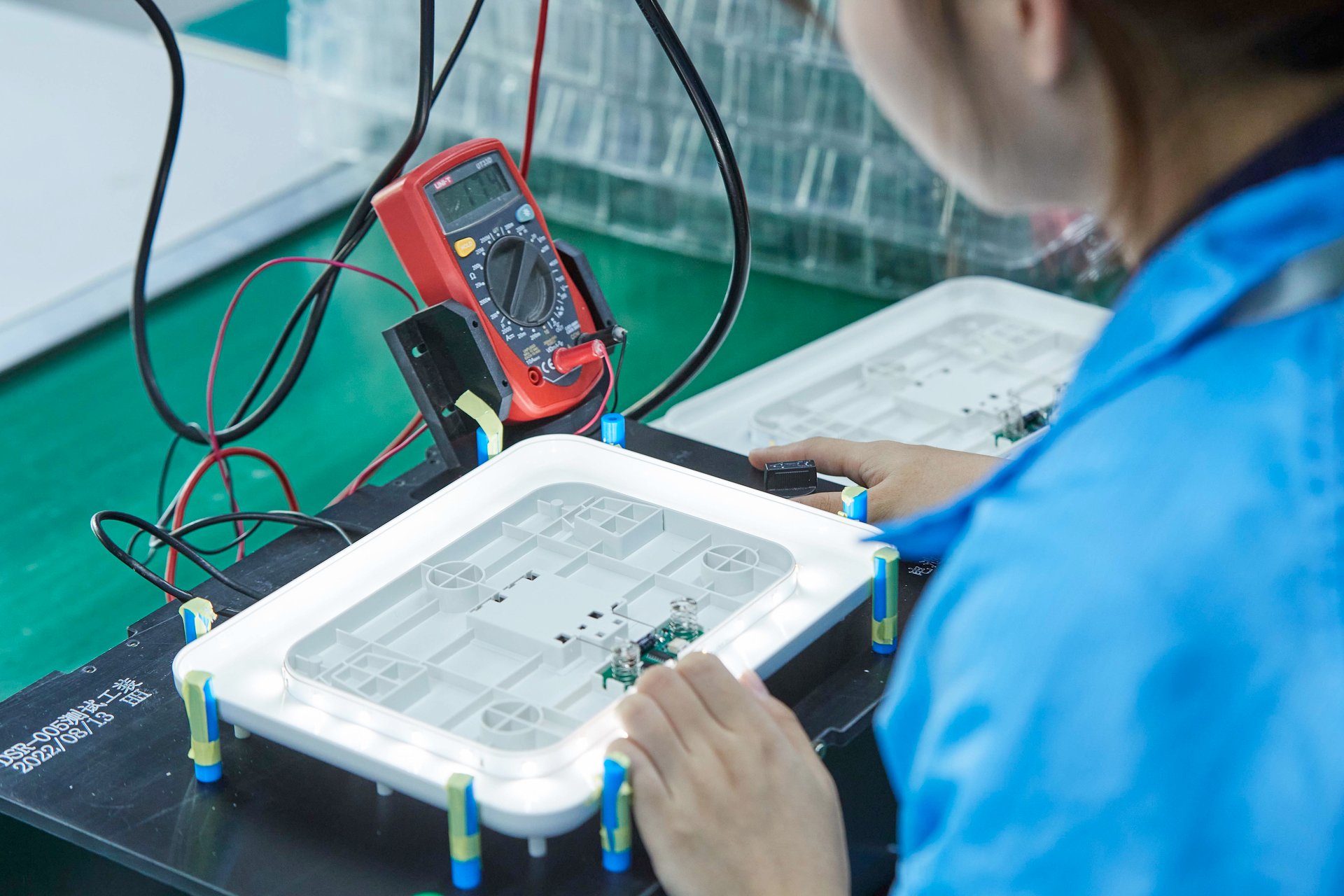

• Producing product - We can produce and distribute this part to you, your consumers, or your retail partners.

• Assembly and package - Our mature supply chain offers a variety of parts procurement. Of course, we also can provide the final assembly and ship as required.

• Less Time - Our manufacturing process allows for a rapid turnaround which saves your time and cost.