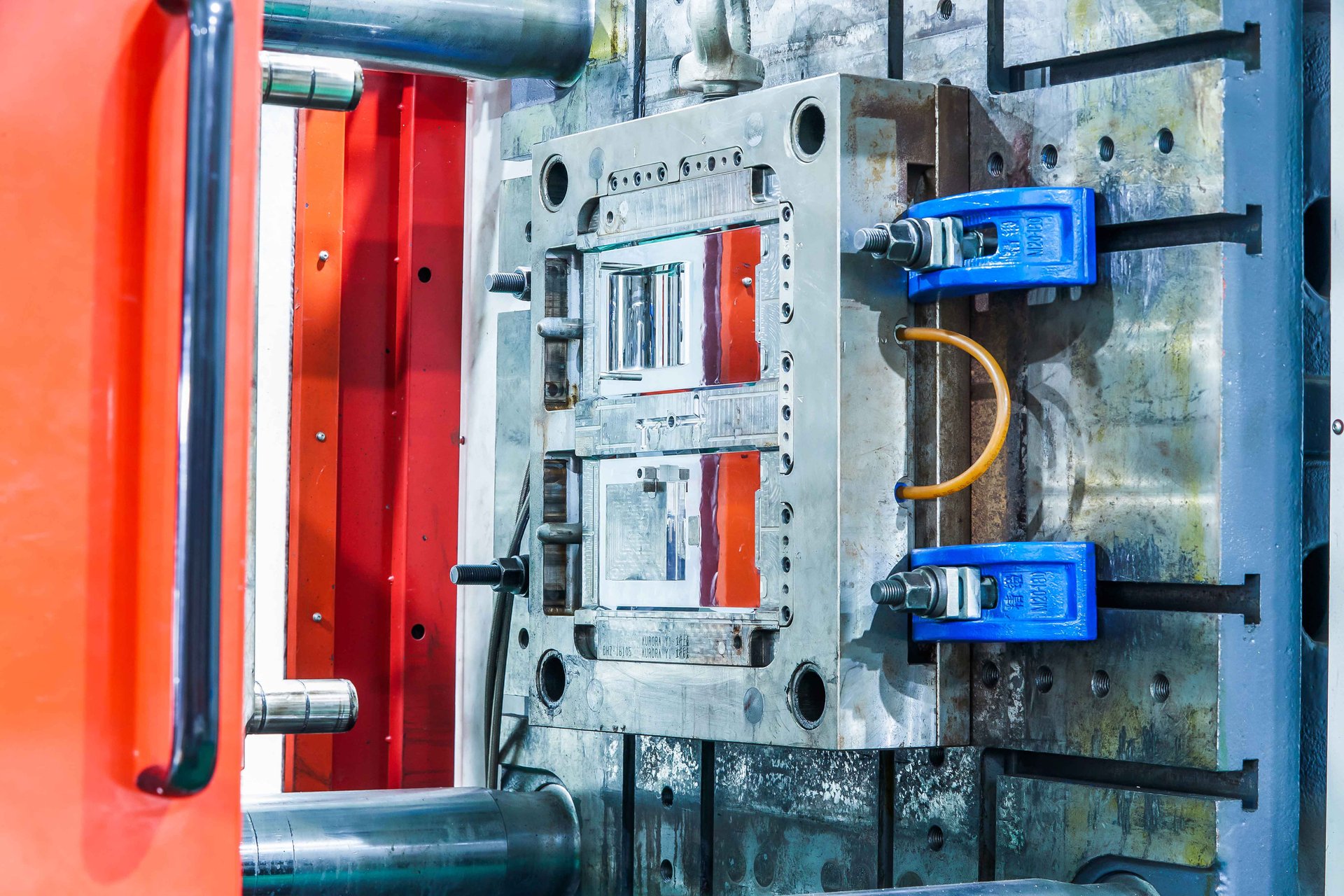

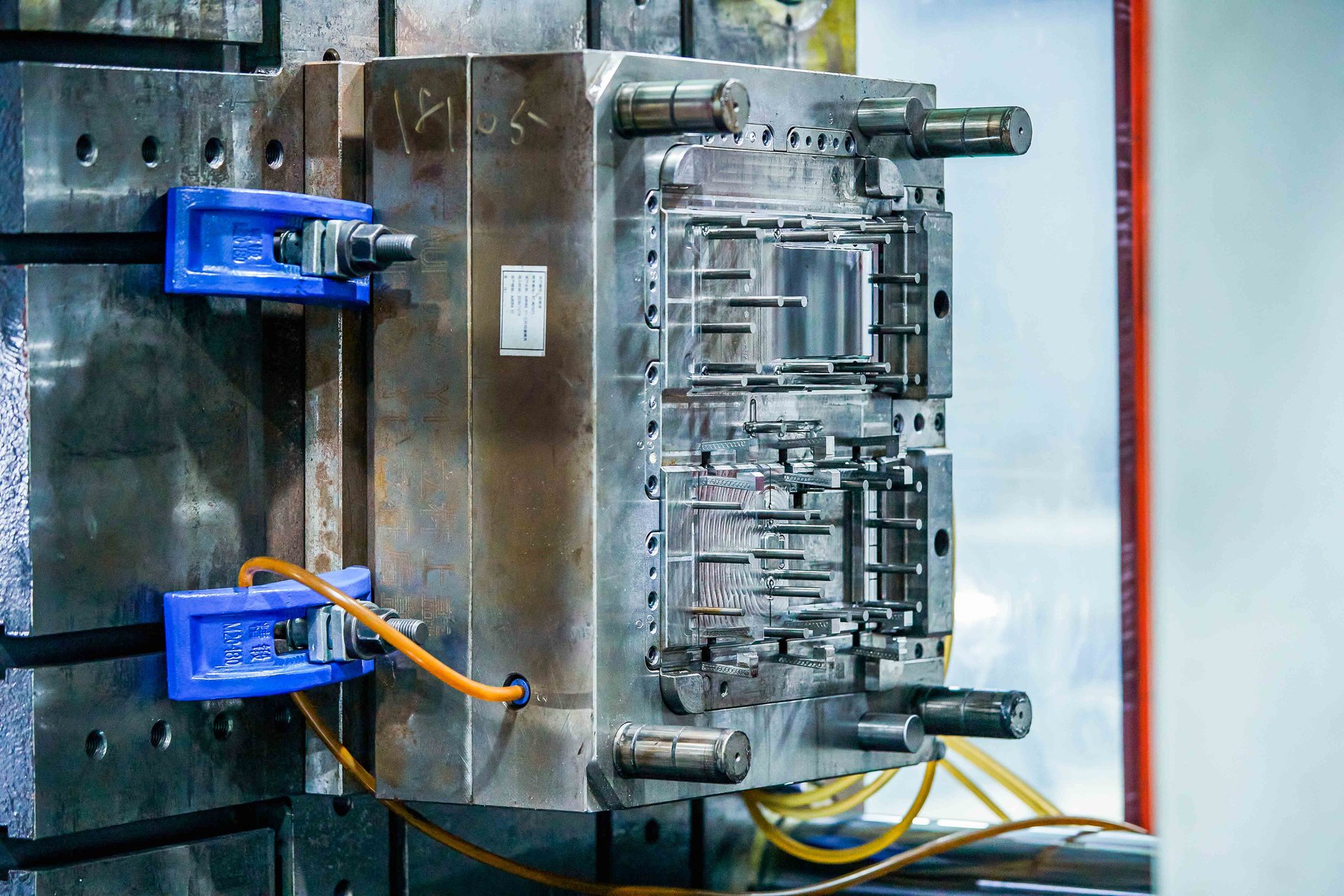

The process of injection molding involves injecting plastic materials into a mold, after cooling and curing, and pushing the mold top plate forward with an ejector rod to generate the desired shape. Plastic injection molding offers consistent quality for mid-to-high volume manufacturing at the lowest cost. Injection of plastics has such advantages that it is widely used in a variety of industries, including building materials, packaging, electricity, agriculture, automobiles, transportation, light industry, petrochemicals, machinery, national defense, and other aspects of our nation's economy and people's lives.

In addition to offering a long-term plastic injection service, Rex delivers high-quality, on-demand plastic injection molded parts in all stages of the project, from design to injection molding.

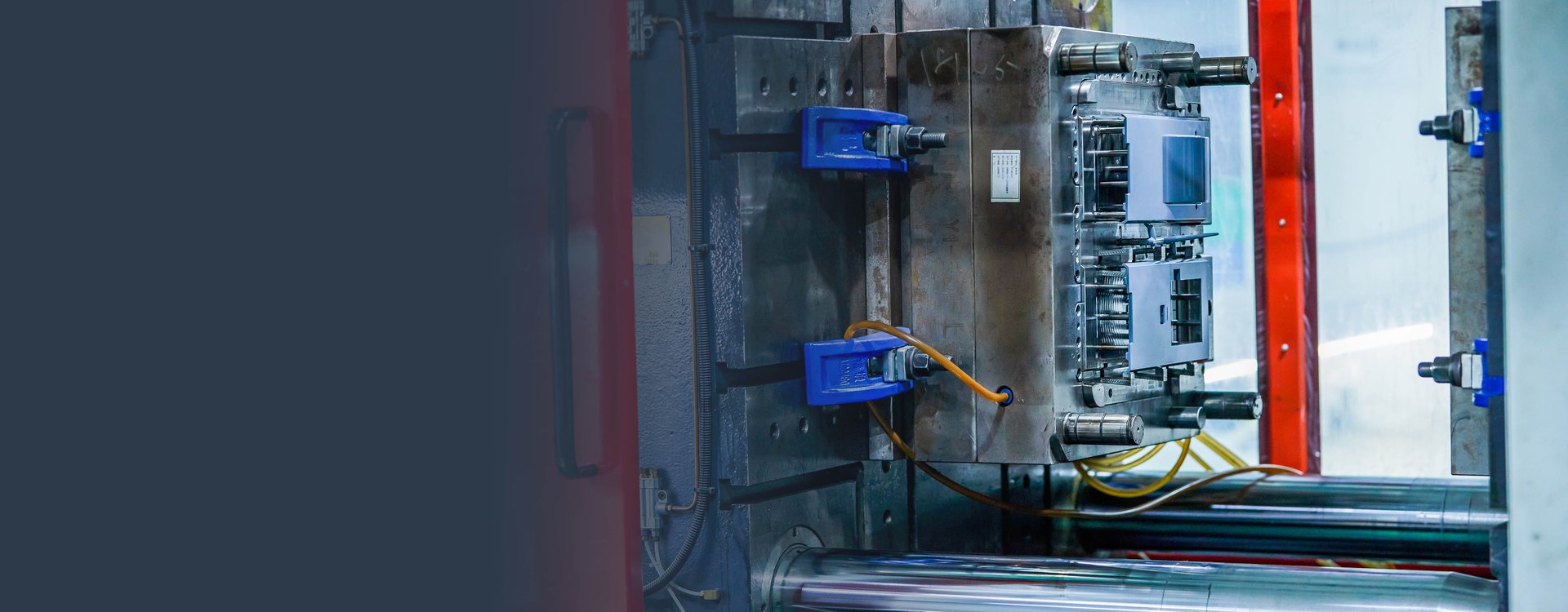

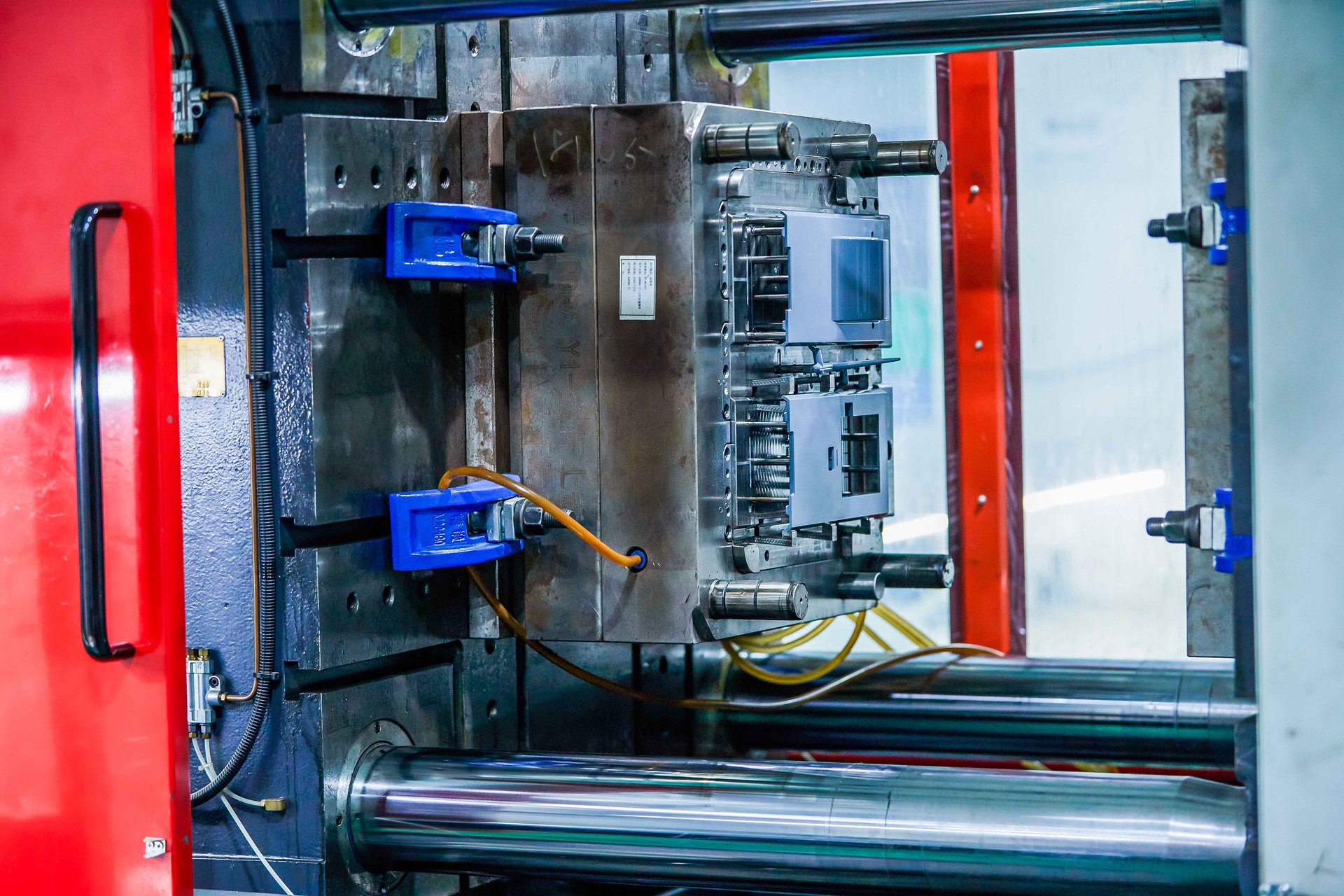

Sophisticated Plastic Injection Molding Machines

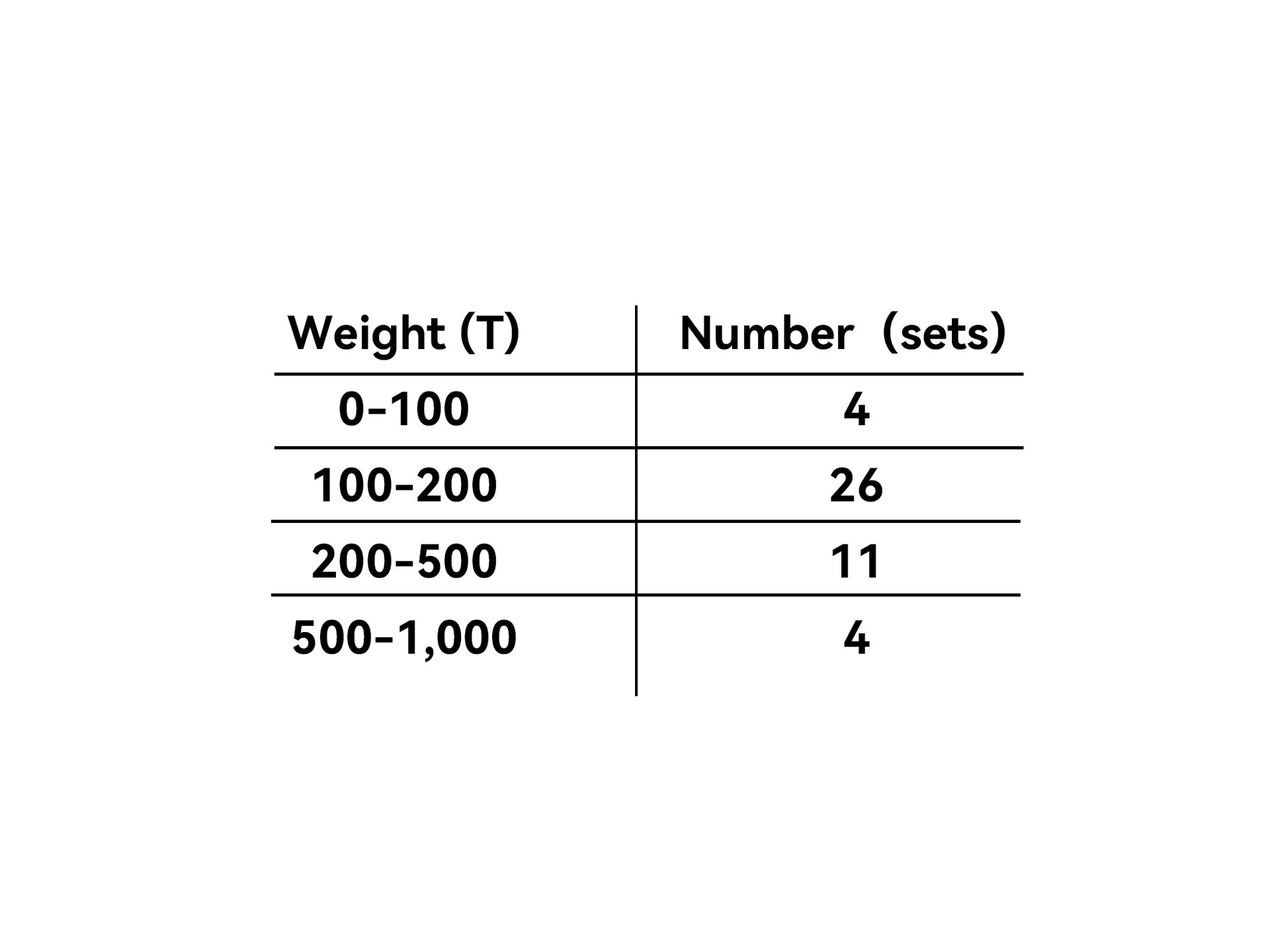

Rex has 45 sets of plastic injection machines that range from 45 tons to 1,000 tons to meet the product size requirements of customers.

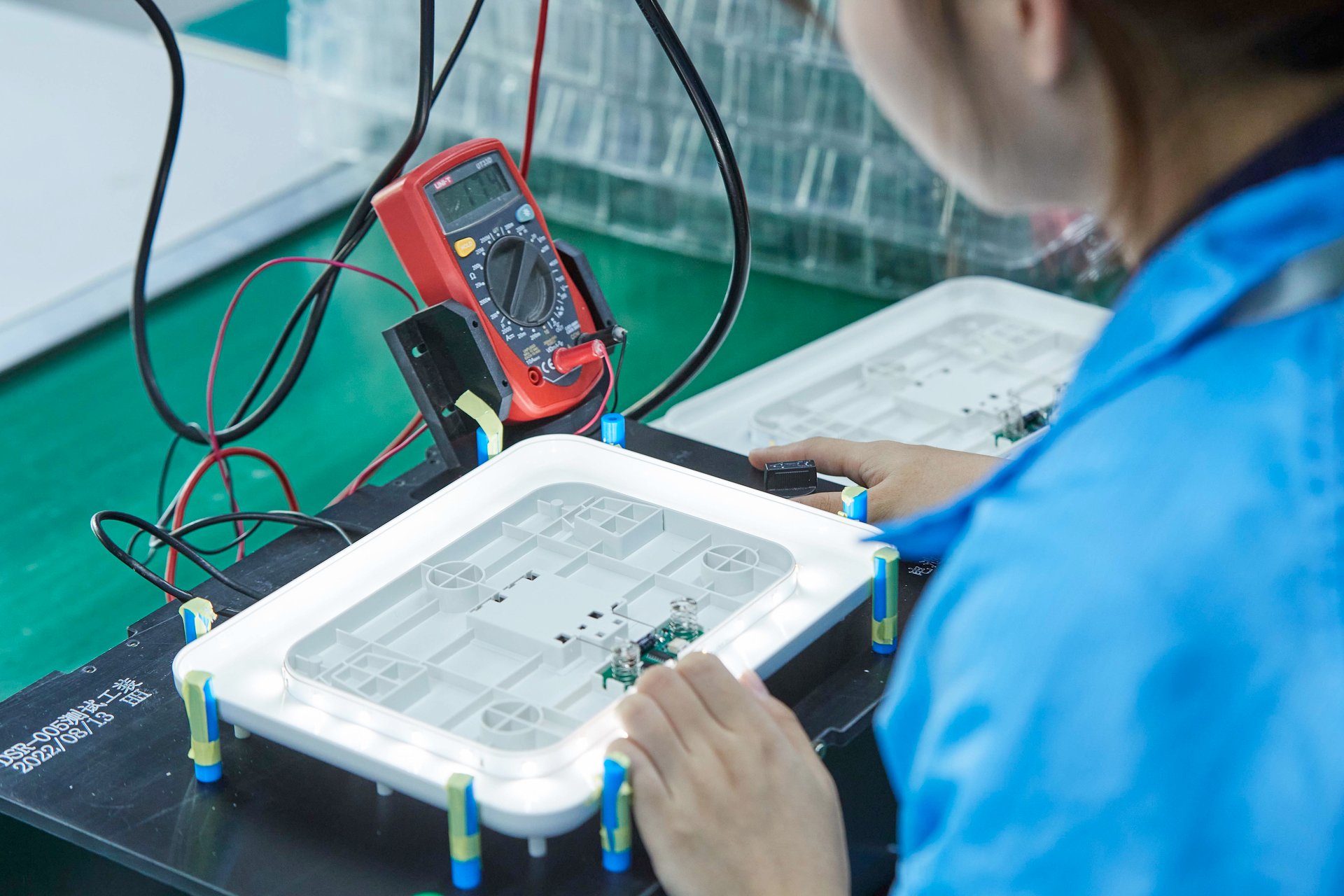

Our One-stop Service Capabilities

Rex offers a one-stop shop for all your manufacturing needs, including product design, plastic injection, and assembly. In the past few decades, Rex has produced top quality parts for a variety of industries, from consumer appliances and automotive parts to military and defense parts.

We offer dedicated sales, customer support, design, and project engineering teams to assist with projects.

Teams responsible for quality control and operations with inspection plans and control plans.

Multiple high-quality equipment and facilities dedicated to rapid mold production and injection molding, with sufficient capacity to meet surges in customer demand on short notice.

Our capability is to ensure that the product meets functional and surface requirements while reducing cost at the same time.