Unlocking Possibilities in EVA Foam Molding with Rex-Your Trusted Supplier

EVA molding stands as a remarkable method for manufacturing plastic products, offering a versatile range of applications. The challenge often lies in finding a reliable supplier who not only possesses rich experience in the molding process but also understands well of material properties and modifications.Rex emerges as the go-to manufacturer dedicated to excellence in foam molding, specializing in both EVA foam injection molding and EVA foam compression molding.

What is EVA Molding

EVA molding refers to the manufacturing process involving Ethylene-Vinyl Acetate (EVA) foam. EVA is a durable and versatile material commonly used for various applications, ranging from athletic shoe soles and padding in sports equipment to packaging and flooring.

EVA Foam Injection Molding

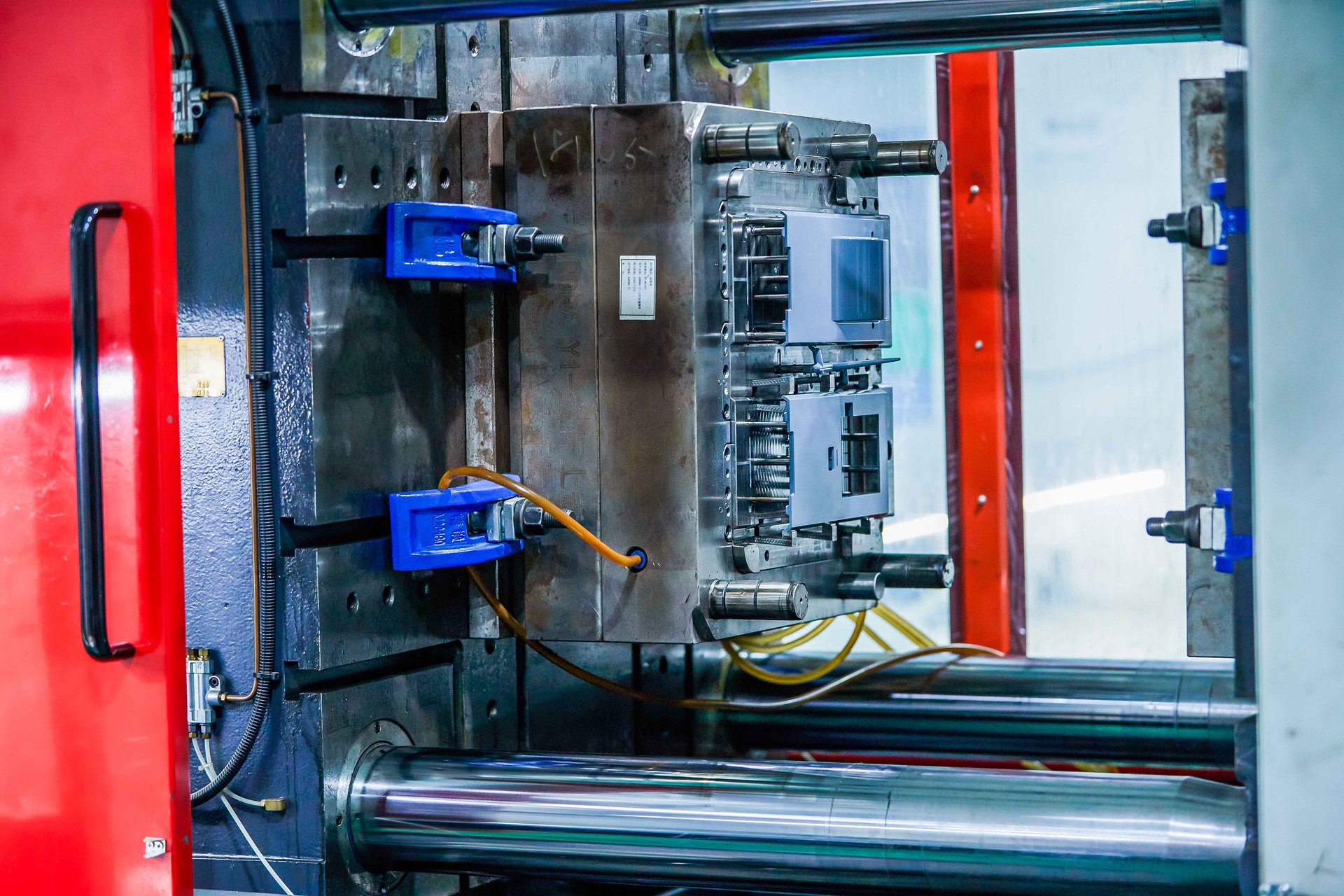

Process Overview: In this method, EVA pellets are melted and injected into a mold cavity under high pressure. The molten EVA then takes the shape of the mold and solidifies, resulting in the desired foam product.

Advantages: EVA foam injection molding allows for intricate designs, precise detailing, and the production of complex shapes. It is commonly used for manufacturing shoe soles, protective enclosures,cushions, toys and other customized products.

EVA Foam Compression Molding

Process Overview: Compression molding involves placing pre-cut EVA foam sheets or pellets into a mold cavity. The mold is then closed, and heat and pressure are applied. The heat causes the EVA to soften and conform to the mold's shape, and pressure ensures uniform distribution.

Advantages: This method is suitable for large-scale production, offering cost-effective solutions for products like flooring, mats and industrial components.

Hot Sale Products

EVA Beach Bag

Eva Double-Layer Pet Cat Litter Mat Pad

EVA Foot Massage Acupressure Mat

EVA Swimming Kickboard

EVA Washable Pet Litter Mat

Blue Cloud EVA Cat Litter Mat

Cute Stylish Mini EVA Tote Handbag

DIY Mini EVA Totes Bag

EVA Beach Bag

EVA Foam for Hikking Poles

EVA Handle Trekking Poles

EVA Tennis Balls

Kids Waterproof Open Tote EVA Bag

Simple Modern EVA Tote Handbag

Waterproof Multi-use Trapping EVA Mat

Our One-stop Service Capabilities

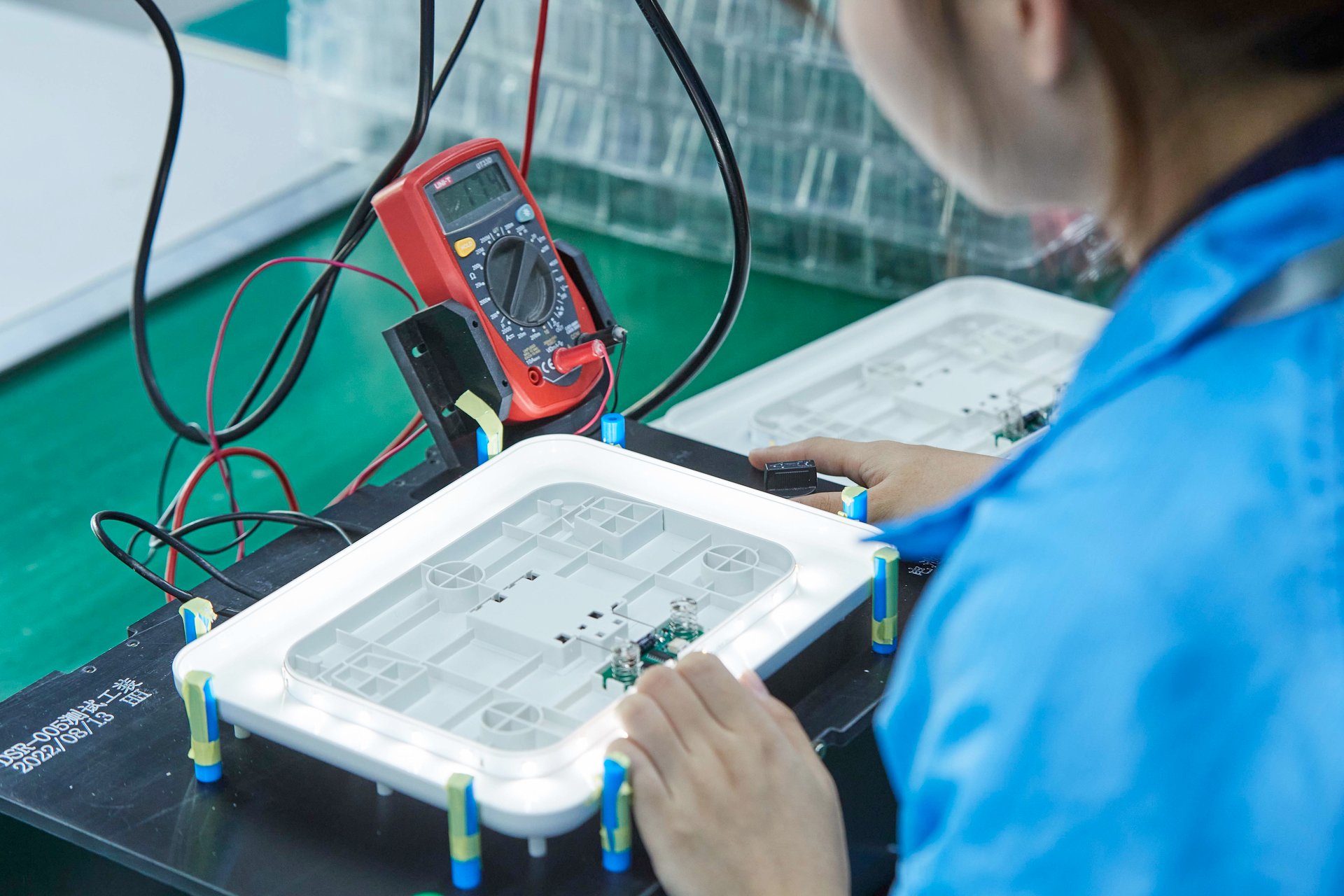

Rex offers a one-stop shop for all your manufacturing needs, including product design, plastic injection, and assembly. In the past few decades, Rex has produced top quality parts for a variety of industries, from consumer appliances and automotive parts to military and defense parts.

We offer dedicated sales, customer support, design, and project engineering teams to assist with projects.

Teams responsible for quality control and operations with inspection plans and control plans.

Multiple high-quality equipment and facilities dedicated to rapid mold production and injection molding, with sufficient capacity to meet surges in customer demand on short notice.

Our capability is to ensure that the product meets functional and surface requirements while reducing cost at the same time.

Why Choose Rex for EVA Molding

Choosing Rex as your EVA manufacturing factory comes with a multitude of advantages that set us apart in the industry. Here are compelling reasons why Rex is the ideal partner for your EVA foam molding needs:

Rex boasts extensive experience in EVA foam molding, with a proven track record of successful projects. Our team possesses in-depth knowledge and expertise in both EVA foam injection molding and EVA foam compression molding.

Beyond being a supplier, Rex offers comprehensive services, guiding clients through every step of the manufacturing process. From initial design consultations to the delivery of finished products, we are committed to ensuring a seamless and successful collaboration.

Rex has expanded its business to cover various types of EVA product manufacturing. This diversification showcases our adaptability and ability to cater to a wide range of industries and applications.

At the heart of our success is our skilled foaming technology. Rex has state-of-the-art techniques, ensuring that each product meets the top standards of quality, durability and performance.

Going beyond conventional molding, Rex integrates development and EVA raw material modification into our services. This approach allows us to tailor solutions to the unique needs of each project, ensuring optimal results.

Our service team is responsive, knowledgeable and dedicated to addressing your inquiries, providing assistance and ensuring a smooth collaboration throughout the manufacturing process.Customer satisfaction is our top priority.

Rex's commitment to excellence goes beyond the basics. We continuously expand our business to cover different types of EVA products manufacturing, keeping pace with evolving industry demands and innovative solutions.

Quality is non-negotiable at Rex. We adhere to strict quality control measures throughout the manufacturing process, ensuring that every product leaving our facility meets or exceeds industry standards.

Rex stands out for its in-depth understanding of material properties. This knowledge allows us to make informed decisions during the molding process, resulting in products that not only meet but surpass expectations.

Rex is committed to continuous innovation. We stay ahead of industry trends, invest in cutting-edge technologies, and adapt to new challenges, ensuring that our clients benefit from the latest advancements in EVA foam molding.

Choosing Rex as your EVA manufacturing factory means choosing a partner dedicated to excellence, innovation and client success. We invite you to explore the endless possibilities of EVA foam products with a supplier who consistently delivers exceptional results.

Choosing Rex as your EVA manufacturing factory means choosing a partner dedicated to excellence, innovation and client success. We invite you to explore the endless possibilities of EVA foam products with a supplier who consistently delivers exceptional results.