Introduction

Mold fabrication is a crucial part of the manufacturing process. It involves creating a mold that accurately reproduces the desired shape of a product. However, if the mold is not fabricated with precision, it can lead to costly defects and delays in production. In this article, we will explore the importance of Precision in Mold Fabrication.

The Impact of Imperfect Molds

Imperfect molds can lead to a variety of issues in the manufacturing process. For example, improperly fabricated molds can cause the final product to have uneven surfaces or dimensions, which can affect its functionality or aesthetic appeal. Additionally, this can result in waste or even complete rework of the product. This can lead to increased costs, lower quality products, and diminished reputation with customers.

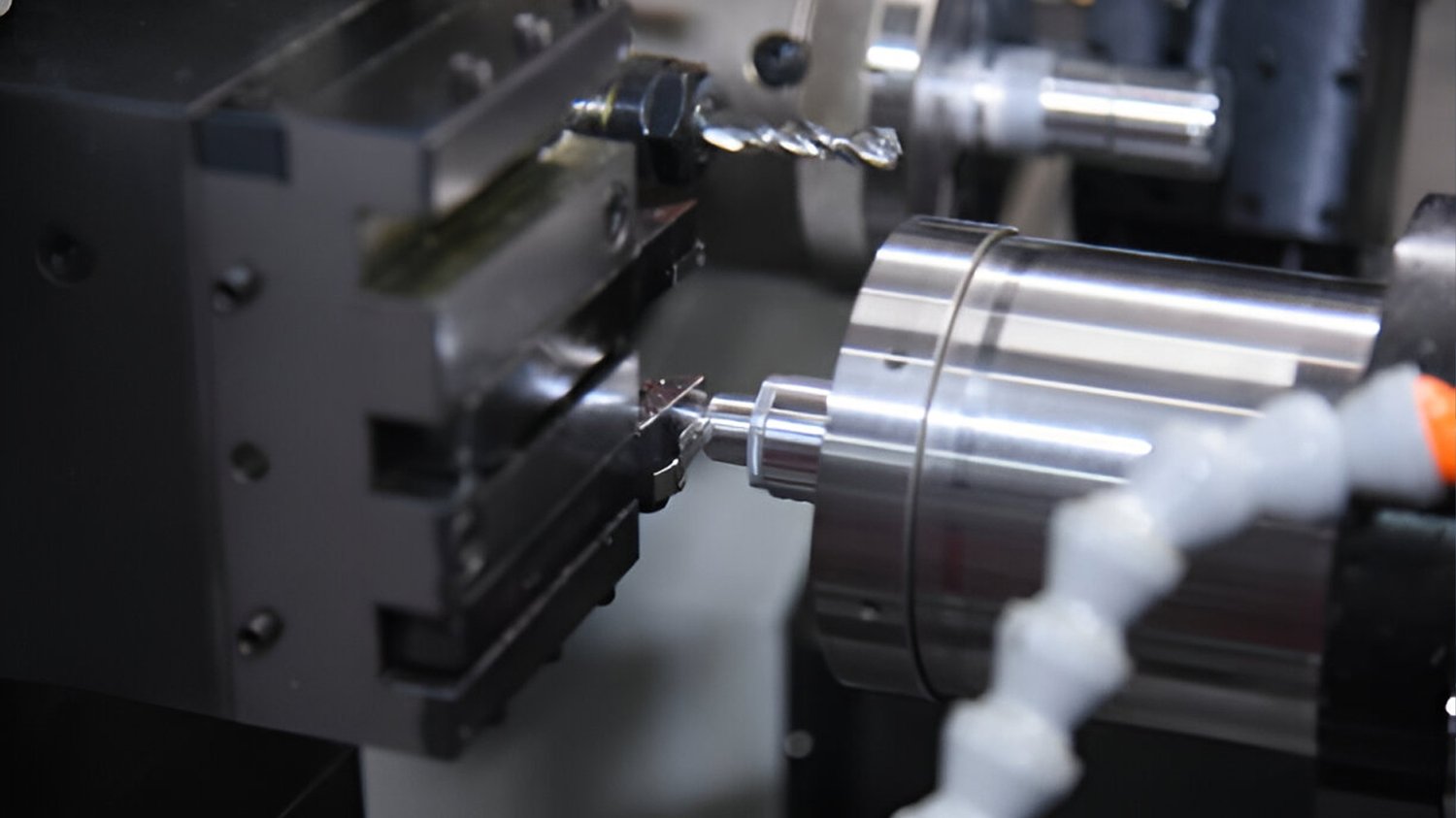

The Role of Technology in Precision Mold Fabrication

Technology plays an important role in ensuring precision during mold fabrication. Advances in computer-aided design (CAD) and manufacturing (CAM) systems allow for more accurate and consistent molds. These systems can verify measurements and simulate the manufacturing process, which can identify potential issues and prevent them from occurring. Additionally, 3D printing is allowing for more precise molds to be created in less time than with traditional methods.

The Importance of Proper Material Selection

The material used for mold fabrication can also affect precision. Depending on the product being created, the mold may need to withstand high temperatures, pressures, or corrosive substances. Failing to select the appropriate material can result in warping or cracking, which can compromise the accuracy of the mold and the final product. Selecting the right material is key for accurate and effective mold fabrication.

The Necessity of Skilled Craftsmanship

While technology and materials are important, skilled craftsmanship is equally essential for precision mold fabrication. Experienced professionals bring a level of expertise that can identify potential issues and solve problems quickly. They have the training and knowledge to use the technology and materials to their fullest potential, which results in higher quality molds and better final products.

The Benefits of Precision Mold Fabrication

There are many benefits of precision mold fabrication. First and foremost, precise molds result in higher quality products. They improve production efficiency and reduce costs by reducing waste and decreasing the need for rework. Precise molds also allow for greater design flexibility, which can enhance product aesthetics and functionality. Finally, precision molds can improve customer satisfaction by ensuring consistent quality and reliability in products.

The Importance of Communication

Effective communication between the design team and the fabrication team is critical for achieving precision in mold fabrication. The design team must provide accurate specifications and expectations, while the fabrication team must communicate any issues or concerns that arise. This collaboration ensures that the final product meets the design intent and is of the highest quality possible.

The Role of Quality Control

Quality control must be built into the process of mold fabrication to ensure precision. This includes regular inspections and testing of the molds throughout the production process. This allows for any issues to be identified and addressed before they affect the final product. Quality control measures can also provide data for continuous improvement in the fabrication process.

The Need for Continuous Improvement

Continuous improvement in mold fabrication is essential for ensuring precision. This includes analyzing data from quality control measures, seeking feedback from customers and employees, and implementing technological advancements. Continuous improvement ensures that the fabrication process is always evolving and producing higher quality molds and products.

The Bottom Line

Precision mold fabrication is necessary for the manufacturing of high-quality products. Achieving precision requires skilled craftsmanship, the use of advanced technology, proper material selection, effective communication, quality control, and continuous improvement. Efforts to improve the precision of mold fabrication can lead to reduced costs, higher quality products, and improved customer satisfaction.