The Advantages and Process of Plastic Injection Molding

Introduction:

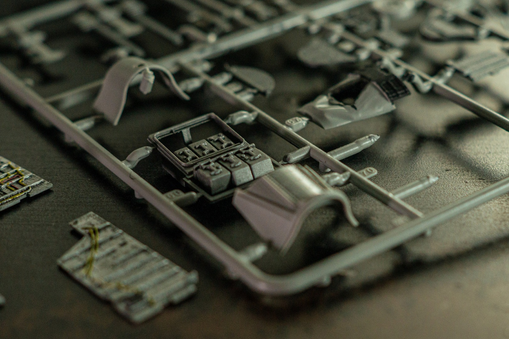

Plastic injection molding is one of the most popular manufacturing processes in the world today. It is used to produce a wide range of plastic products in various industries. This process involves the melting of plastic pellets and injecting them into a mold to form the desired shape. In this article, we will explore the advantages of plastic injection molding, the process involved, and the applications of this manufacturing method.

Advantages of Plastic Injection Molding:

High Precision: Plastic injection molding offers high precision and accuracy in the production of complex and intricate shapes. It is ideal for producing products with intricate details and complex geometries.

Large Scale Production: This method can produce large quantities of plastic products at a low cost. The process is automated, which means that it can run continuously with minimal supervision, increasing production efficiency.

Versatility: Injection molding can use a wide range of plastic materials, including thermoplastics, thermosets, and elastomers. This versatility makes it ideal for producing a wide range of plastic products.

Low Waste: The process of injection molding generates very little waste as the leftover material can be reused to make other products. This makes it an environmentally friendly manufacturing method.

High Strength: Injection molding produces plastic products that are strong and durable. They can withstand high temperatures and pressures, making them ideal for use in different environments.

Process of Plastic Injection Molding:

The plastic injection molding process involves the following steps:

Designing the Mold: The first step is to design the mold that will be used to produce the plastic product. This involves creating a 3D model of the desired product using computer-aided design (CAD) software.

Preparing the Material: The plastic pellets are then melted and mixed with additives to enhance their properties. This mixture is then injected into the mold.

Injection: The molten plastic mixture is then injected into the mold under high pressure. The pressure ensures that the plastic fills every part of the mold, creating an exact replica of the 3D model.

Cooling: The mold is then cooled to solidify the plastic. This is done by either circulating cool air or running cold water through the mold.

Ejection: Once the plastic has solidified, the mold is opened, and the plastic product is ejected from the mold.

Applications of Plastic Injection Molding:

Plastic injection molding is used in various industries to produce a wide range of products, including:

Automotive Parts: Plastic injection molding is used to produce various automotive parts, such as bumpers, dashboards, and interior trims.

Packaging: Injection molding is used to produce different types of packaging, including food containers, bottles, and caps.

Medical Devices: Injection molding is used to produce medical devices such as syringes, inhalers, and IV components.

Conclusion:

Plastic injection molding is an efficient and cost-effective manufacturing method that offers high precision, versatility, and low waste. The process involves designing the mold, preparing the material, injection, cooling, and ejection. This method is used in various industries, including automotive, packaging, medical, and toys. As technology advances, plastic injection molding will continue to play a critical role in the production of plastic products.