Injection Mold vs. Blow Mold: Which is the Better Option for Your Project

When it comes to manufacturing plastic products, choosing the right molding process is crucial for the success of your project. Two popular methods used in the industry are injection molding and blow molding. Each of these techniques has its own advantages and limitations, making it important to understand their differences before making a decision. In this article, we will explore the characteristics and benefits of injection molding and blow molding, helping you determine which option is the better fit for your project.

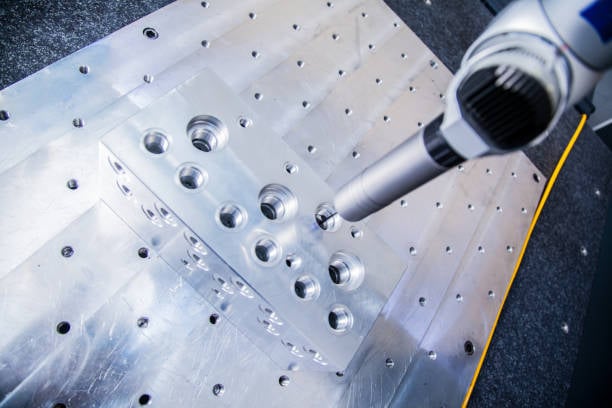

1. The Basics of Injection Molding

Injection molding is a widely used manufacturing process that involves injecting molten plastic material into a mold cavity. The molten plastic solidifies inside the mold, creating the desired shape. This process is commonly used for producing complex and intricate plastic parts with high precision.

Injection molding offers several advantages, including:

- High production efficiency

- Precision and repeatability

- Wide range of materials

- Ability to incorporate various features

However, injection molding also has some limitations. It requires high initial tooling costs, making it more suitable for high-volume production. Additionally, the complexity of the process may result in longer lead times.

2. Understanding Blow Molding

Blow molding, on the other hand, is a process used for manufacturing hollow plastic parts. It involves melting plastic resin and then blowing air into it to form the desired shape. This technique is commonly used for producing bottles, containers, and other hollow objects.

The advantages of blow molding include:

- Cost-effectiveness for large-scale production

- Ability to produce lightweight parts

- Good impact resistance

- Quick production cycle times

However, blow molding does have some limitations. It is not suitable for producing complex shapes, as it is difficult to achieve intricate details. The process is also less precise compared to injection molding.

3. Factors to Consider when Choosing

When deciding between injection molding and blow molding for your project, several factors need to be taken into consideration:

Production Volume

If you require a large volume of parts, injection molding is generally the better option. It offers high production efficiency and cost-effectiveness for large-scale production runs. On the other hand, blow molding is more suitable for smaller production volumes.

Part Complexity

If your project involves complex and intricate parts, injection molding is the way to go. It allows for the production of complex geometries and precise details that cannot be achieved with blow molding.

Material Selection

Both injection molding and blow molding support a wide range of materials. However, if you require specific material properties such as heat resistance or chemical resistance, injection molding provides more flexibility in material selection.

Lead Time

Injection molding typically has longer lead times compared to blow molding. If you have time constraints for your project, blow molding may be a more suitable option as it offers quicker production cycle times.

Cost Considerations

Injection molding requires high initial tooling costs, which can be a significant investment. For smaller production volumes, blow molding may be a more cost-effective choice.

4. Conclusion

Injection molding and blow molding are two distinct processes with their own set of advantages and limitations. The choice between these two techniques depends on various factors such as production volume, part complexity, material selection, lead time, and cost considerations. By considering these factors carefully, you can determine which option, injection molding or blow molding, is the better fit for your project.