Introduction

Epoxy injection molding is a revolutionary manufacturing process that has gained significant popularity in recent years. This technique enables the production of high-quality and intricately designed parts with superior precision and strength. In this article, we will explore the various aspects of epoxy injection molding, including its process, benefits, applications, and future prospects.

The Process of Epoxy Injection Molding

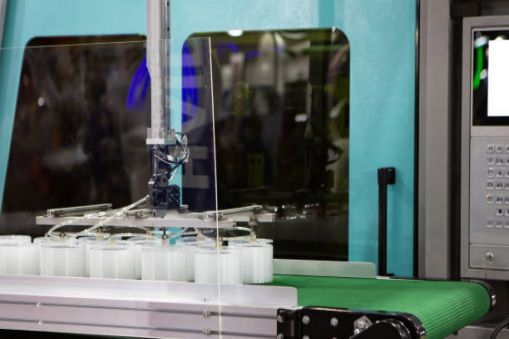

Epoxy injection molding involves the use of epoxy resins, which are mixed with a hardener and injected into a mold under high pressure and temperature. The resin mixture fills the mold cavity, creating a detailed and accurate replica of the desired part. Once the resin cures and hardens, the mold is opened, and the finished part is removed.

Benefits of Epoxy Injection Molding

Epoxy injection molding offers numerous advantages over traditional manufacturing methods. Firstly, it allows for the production of complex shapes and intricate designs that are difficult to achieve with other processes. The high pressure and temperature during the injection process ensure that the resin completely fills even the smallest details of the mold, resulting in precise and highly detailed parts.

Secondly, epoxy injection molding provides exceptional dimensional stability. The curing process ensures that the finished parts maintain their shape and size, even in harsh environments or under extreme temperature variations. This makes epoxy injection molded parts suitable for a wide range of applications, including automotive, aerospace, electronics, and medical industries.

Furthermore, epoxy injection molding offers excellent mechanical properties. The cured epoxy resin exhibits high strength, rigidity, and resistance to impact and wear. This makes it an ideal choice for producing durable and long-lasting parts that can withstand demanding conditions.

Applications of Epoxy Injection Molding

The versatility of epoxy injection molding allows it to be used in various industries and applications. One of the key sectors benefiting from this process is the automotive industry. Epoxy injection molded parts are used in engine components, interior and exterior trims, electrical connectors, and brake systems. The ability to produce lightweight and high-strength parts makes epoxy injection molding an attractive choice for automotive manufacturers.

In the aerospace industry, epoxy injection molding is utilized for producing lightweight and aerodynamic parts, such as wing components, fuselage sections, and engine housings. The precision and strength of epoxy injection molded parts contribute to the overall performance and safety of aircraft.

Another significant application of epoxy injection molding is in the electronics industry. This process is used to manufacture electronic enclosures, connectors, and circuit boards. The dimensional stability and excellent electrical insulation properties of epoxy resin make it an ideal material for these applications.

In the medical field, epoxy injection molding is employed in the production of medical devices, implants, and surgical instruments. The biocompatibility and sterilizability of epoxy resin ensure that the manufactured parts meet the highest standards of safety and reliability.

The Future of Epoxy Injection Molding

The future of epoxy injection molding looks promising, as advancements in materials and technology continue to enhance its capabilities. Researchers are exploring the use of new epoxy formulations that offer improved thermal and chemical resistance, enabling the production of parts suitable for even more demanding applications.

Additionally, the integration of additive manufacturing techniques with epoxy injection molding is being investigated. This combination allows for the creation of complex geometries and the incorporation of functional features directly into the mold, further expanding the possibilities of epoxy injection molding.