Introduction

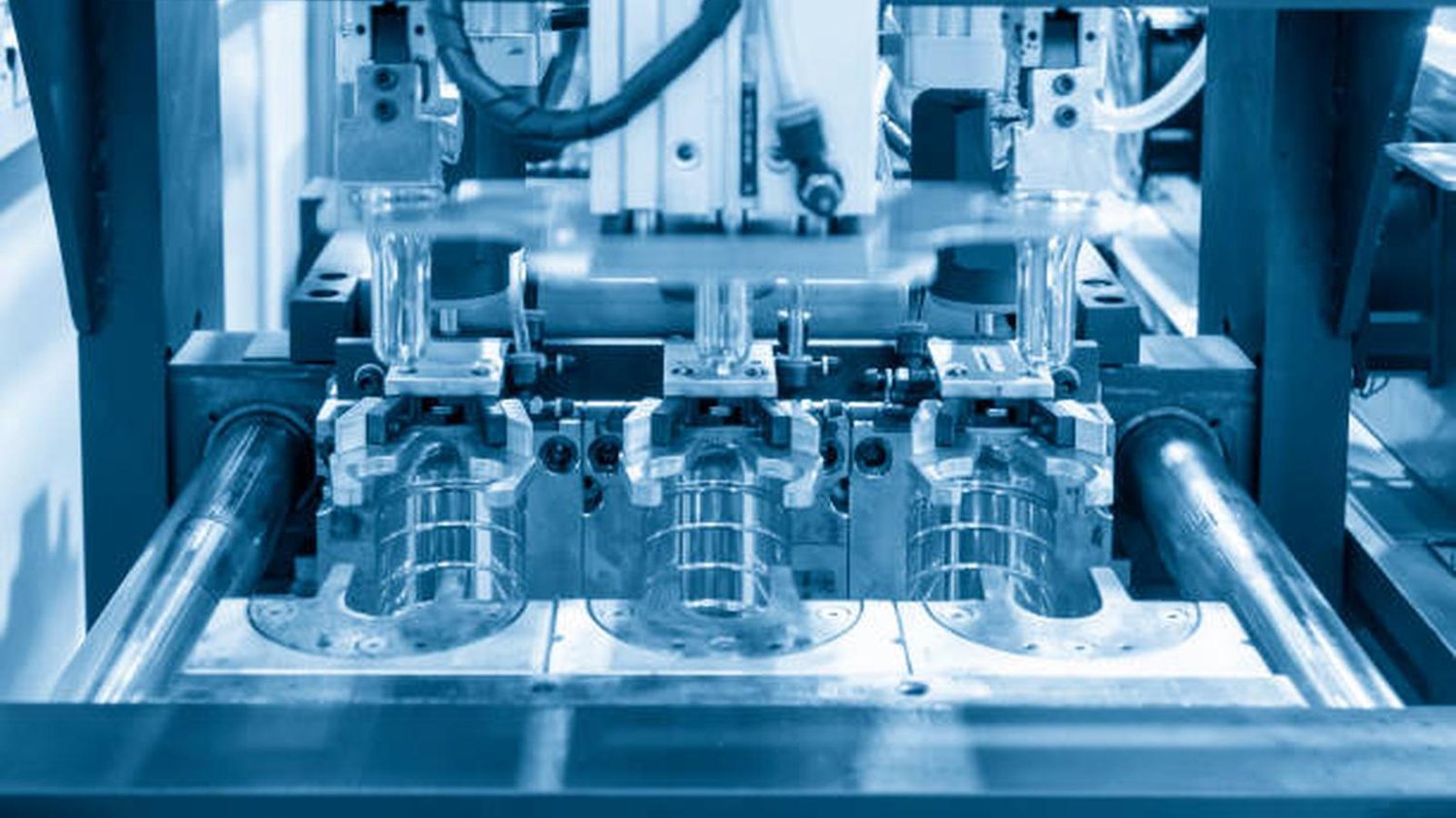

Plastic injection mold is a popular manufacturing process that is used in various industries. It is a cost-effective method that is used to produce high-quality plastic parts in large volumes. This process involves melting plastic pellets and injecting them into a mold cavity, where they cool and solidify into the desired shape. In this article, we will discuss the benefits of plastic injection mold for modern manufacturing.

The Advantages of Plastic Injection Mold

-

High Efficiency and Precision

Plastic injection mold is a highly efficient process that can produce large volumes of plastic parts in a short amount of time. It is also a precise method that can produce complex shapes and designs with high accuracy. This is achieved by using computer-aided design (CAD) software and advanced molding equipment.

-

Versatility

Plastic injection mold is a versatile process that can be used to produce a wide range of plastic parts. This includes everything from small components to large, complex structures. It can also be used to produce parts in a variety of shapes and sizes, making it ideal for a range of applications.

-

Cost-effective

One of the main benefits of plastic injection mold is its cost-effectiveness. This process is relatively inexpensive compared to other manufacturing methods, such as machining and casting. It also produces less waste, which can further reduce costs.

-

Consistency and Quality

Plastic injection mold is a highly consistent process that produces high-quality parts with minimal variation. This is achieved by using advanced molding equipment and maintaining strict quality control standards. As a result, plastic parts produced using this method are highly reliable and durable.

-

Environmentally Friendly

Plastic injection mold is a relatively environmentally friendly process. It produces less waste than other manufacturing methods, and the waste that is produced can be recycled. Additionally, the materials used in the process are non-toxic and can be safely disposed of.

Conclusion

Plastic injection mold is a highly efficient and cost-effective method that is used in a wide range of industries. It offers a range of benefits, including high precision, versatility, consistency, and quality. Additionally, it is a relatively environmentally friendly process that produces less waste than other manufacturing methods. If you are looking for a reliable and cost-effective way to produce plastic parts, plastic injection mold is definitely worth considering.