You must first become familiar with the ins and outs of an injection mold if you want to comprehend how it functions. This is a brief introduction to the fundamentals of injection molding tools. Check out our comprehensive guide if you want even more details.

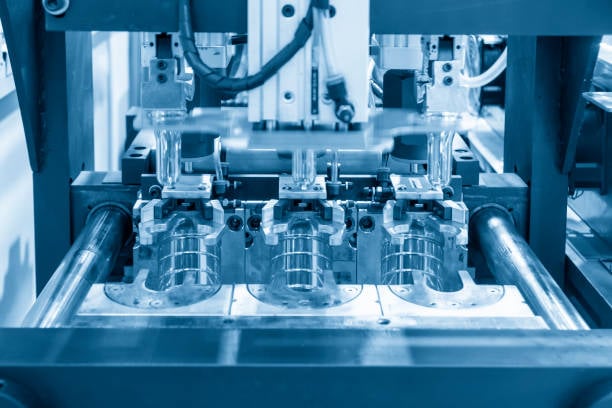

One of the specially crafted instruments used in plastic injection molding to shape molten plastic into plastic items is an injection mold. These molds are created by manufacturers for particular plastic goods they will make.

A two-plate tool is the most popular type of injection mold. There are many varieties of injection molds. The injection mold (A Plate) and the ejector mold are the two primary components of the two-plate tool (B Plate). A clamping device is used to secure these plates to platens. There is a natural division or split known as the parting line that occurs when these plates come together to form the injection mold.

The Injection Mold (A Plate)

Molten plastic is transported from the injection unit to the injection mold through the injection mold (A Plate). Sprue bushing refers to the opening or entrance of the injection mold (A Plate). The sprue bushing is joined to the sprue, a channel that connects the runners to the molten plastic. The sprue and the gates, or entrances, of the cavity image are connected by runners, which are tunnels or channels. Molten plastic is guided to the cavity image by runners.

The Cavity Image

The injection mold's cavity image, which takes the form of the desired plastic product, is an empty area inside the mold. Single or numerous cavities can be found in injection molds.

Single impression cavity molds are injection mold tools with only one cavity image. Multiple impression cavity molds are those that have two or more cavity images. More than 128 cavity images can be found in some molds.

The Ejector Mold (B Plate)

The exit point through which the plastic product is ejected from the injection mold is the ejector mold (B Plate). When the plastic product is ready, the clamping unit opens the injection mold by moving the ejector mold (B Plate) away from the injection mold (A Plate). Circular pins known as ejector pins force the plastic product off of the injection mold as the mold opens. Naturally, injection molds leave their mark on the plastic goods they create.

The walls of the ejector mold (B Plate) are tapered to enable proper ejection of the plastic product. The draft angle is what is meant here. The plastic product will scrape against the walls of the ejector mold (B Plate) and have difficulty ejecting if there is no draft angle and the walls are 90 degrees. This might harm the plastic that was molded in the mold as well. The molded plastic can be easily ejected with a draft angle because the walls won't make contact and air can rush in to break the vacuum seal.