The Advantages of Plastic Molding in the Manufacturing Industry

Plastic molding is a widely used manufacturing process that involves shaping plastic materials into the desired form. It has revolutionized the production of various products across different industries. This article explores the advantages of plastic molding in the manufacturing industry and highlights its impact on the overall production process.

1. Cost-effectiveness

Plastic molding offers significant cost advantages compared to other manufacturing processes. The initial tooling costs may be higher, but once the molds are created, the production costs are relatively low. The ability to mass-produce plastic parts at a lower cost makes plastic molding an attractive option for businesses.

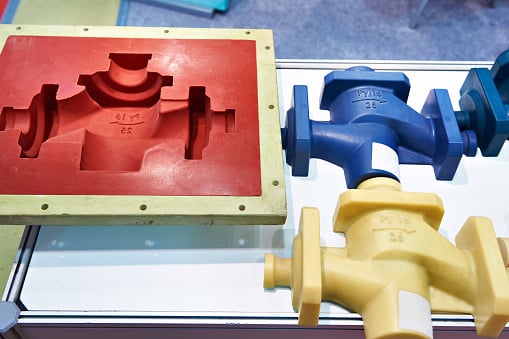

2. Versatility

Plastic molding allows for the production of complex shapes and intricate designs that may be difficult or expensive to achieve using other methods. This versatility makes it a preferred choice for manufacturers in various industries, including automotive, consumer goods, and electronics.

3. Efficiency and Speed

Plastic molding enables high-speed production, reducing the time required to manufacture a large number of parts. The process is highly automated, which minimizes human error and ensures consistent quality throughout the production cycle. This efficiency and speed contribute to faster time-to-market for products.

4. Material Options

Plastic molding supports a wide range of materials, including thermoplastics and thermosetting plastics. This variety allows manufacturers to select the most suitable material based on the desired properties of the final product. Different materials offer different strengths, flexibility, and heat resistance, expanding the possibilities for product development.

5. Environmental Benefits

Plastic molding has made significant advancements in terms of sustainability. Many manufacturers now use recycled plastics or biodegradable materials in the molding process, reducing the environmental impact. Additionally, the high efficiency of plastic molding minimizes waste, as the excess material can be recycled and reused.

Conclusion

Plastic molding has revolutionized the manufacturing industry with its cost-effectiveness, versatility, efficiency, and material options. It offers businesses the ability to produce high-quality products at a lower cost, while also contributing to environmental sustainability. As technology continues to advance, plastic molding is expected to further enhance manufacturing processes and drive innovation in various industries.