In today's fast-paced world, plastic mold manufacturing plays a vital role in various industries. From automotive to electronics, plastic molds are widely used to create a diverse range of products. This article aims to provide a comprehensive guide to plastic mold manufacturing, covering everything from the process to the benefits.

What is Plastic Mold Manufacturing?

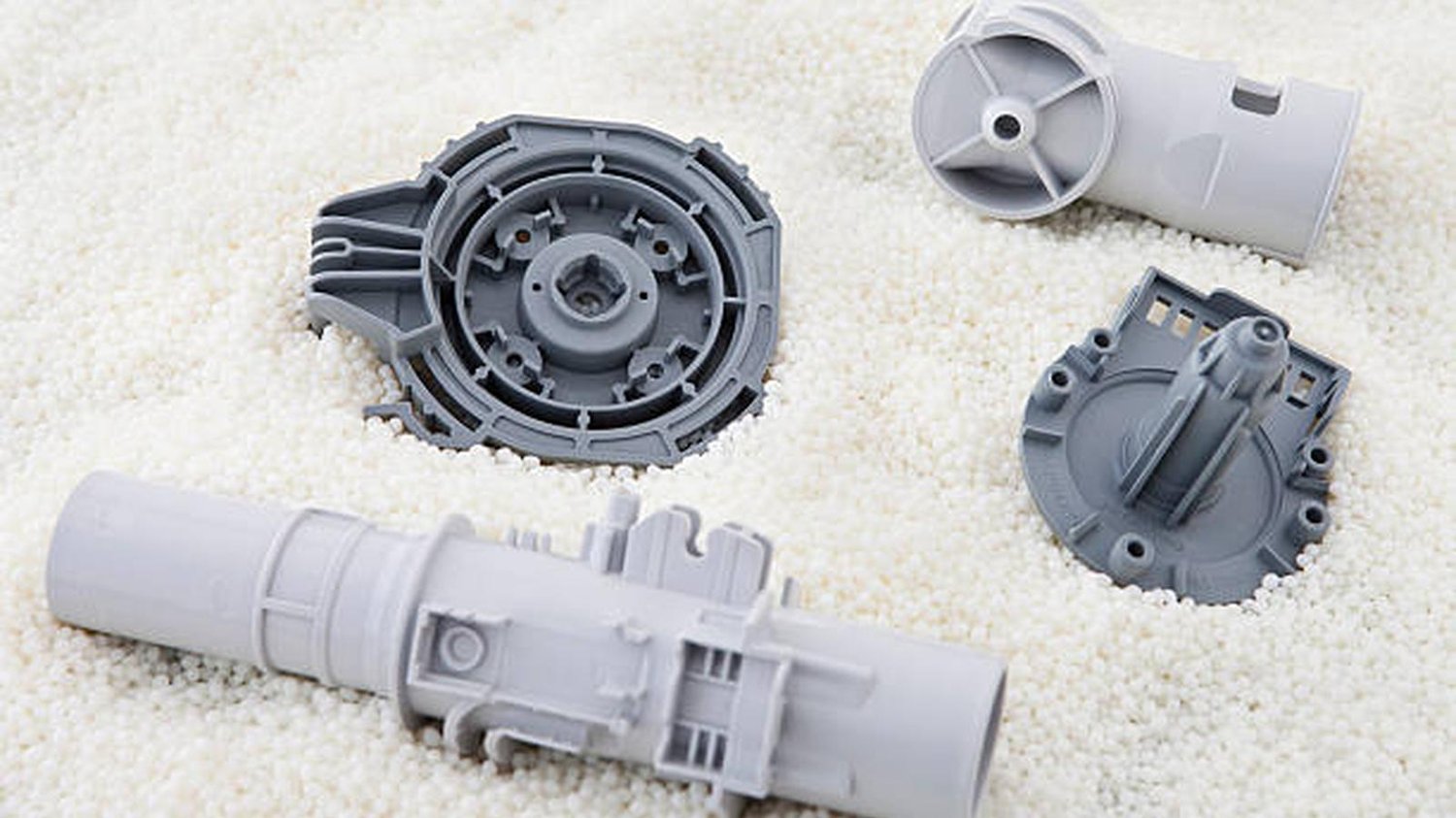

Plastic mold manufacturing is the process of creating molds or tooling for the production of plastic parts. It involves the design, development, and fabrication of molds that enable the mass production of plastic components in various shapes and sizes. These molds are typically made from materials like steel or aluminum and are used in injection molding machines.

The Process of Plastic Mold Manufacturing

The process of plastic mold manufacturing involves several steps:

- Design: The first step is to design the mold using computer-aided design (CAD) software. The design includes the specifications of the product, such as its dimensions, shape, and features.

- Material Selection: Once the design is finalized, the next step is to select the appropriate material for the mold. Factors like durability, heat resistance, and cost are considered during material selection.

- Tooling: After material selection, the mold is fabricated using precision tools and machinery. This involves cutting, shaping, and finishing the mold to meet the desired specifications.

- Injection Molding: Once the mold is ready, it is mounted onto an injection molding machine. The machine injects molten plastic into the mold cavity, where it cools and solidifies to form the desired plastic part.

- Quality Control: After the plastic parts are produced, they undergo rigorous quality control checks to ensure they meet the required standards. This includes dimensional checks, visual inspections, and functional testing.

The Benefits of Plastic Mold Manufacturing

Plastic mold manufacturing offers numerous benefits:

- Cost-Effectiveness: Plastic mold manufacturing enables the mass production of plastic parts at a lower cost per unit. This makes it an economical choice for various industries.

- Design Flexibility: With plastic mold manufacturing, it is possible to create complex and intricate designs that would be difficult or impossible with other manufacturing processes.

- Fast Production: Plastic mold manufacturing allows for high-volume production, resulting in faster turnaround times and increased productivity.

- Consistency: The use of molds ensures consistent quality and dimensional accuracy in the produced plastic parts.

- Durability: Plastic molds are made from durable materials like steel or aluminum, ensuring longevity and repeated use.

Conclusion

Plastic mold manufacturing is a crucial process that enables the mass production of plastic parts. With its cost-effectiveness, design flexibility, and fast production capabilities, it has become an integral part of various industries. Whether it's automotive, electronics, or consumer goods, plastic mold manufacturing plays a significant role in shaping the products we use every day.