Plastic Injection Molding: A Comprehensive Guide

Plastic injection molding is a widely used manufacturing process in the e-commerce industry. It involves the production of plastic parts by injecting molten plastic into a mold cavity. This versatile technique allows for the creation of complex and intricate shapes, making it ideal for a variety of products.

Understanding the Plastic Injection Molding Process

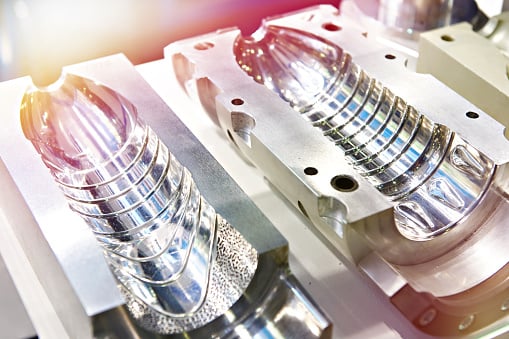

The plastic injection molding process begins with the design of a mold. The mold is typically made from steel and consists of two halves, the cavity and the core. The molten plastic is injected into the mold under high pressure, filling up the cavity and taking the shape of the desired part. Once the plastic cools and solidifies, the mold is opened, and the part is ejected.

One of the advantages of plastic injection molding is its ability to produce large quantities of parts with high precision and consistency. The process is highly automated, allowing for fast and efficient production. Additionally, the mold can be designed to incorporate multiple cavities, further increasing the production capacity.

Applications of Plastic Injection Molding

Plastic injection molding is used in various industries, including automotive, electronics, medical, and consumer goods. It is commonly employed in the production of components such as housings, enclosures, knobs, handles, and connectors. The process is also suitable for manufacturing complex parts with intricate geometries, ensuring the final product meets the required specifications.

The automotive industry extensively relies on plastic injection molding for the production of interior and exterior components. These include dashboard panels, door handles, bumpers, and various other parts. The high strength and durability of plastic make it an excellent choice for such applications.

In the electronics industry, plastic injection molding is used to manufacture casings and enclosures for electronic devices. The process allows for the integration of features such as snap-fit assemblies, screw bosses, and internal supports, ensuring efficient assembly and functionality of the final product.

Choosing the Right Material

When it comes to plastic injection molding, selecting the right material is crucial. The choice of material depends on factors such as the intended application, desired mechanical properties, and cost considerations. Common materials used in injection molding include polypropylene, ABS, polycarbonate, nylon, and PVC.

Polypropylene is a versatile thermoplastic that offers excellent chemical resistance, impact strength, and low cost. ABS is known for its high impact resistance and good dimensional stability. Polycarbonate is valued for its transparency, high heat resistance, and impact strength. Nylon is a popular choice for its strength, toughness, and wear resistance. PVC is often used for its low cost and good electrical insulation properties.

The Benefits of Plastic Injection Molding

Plastic injection molding offers numerous advantages over other manufacturing processes. Firstly, it allows for high production volumes, making it suitable for mass production. The process is also highly repeatable, ensuring consistent part quality.

Furthermore, plastic injection molding enables the production of parts with complex geometries and intricate details. It offers design flexibility, allowing for the incorporation of features such as undercuts, threads, and thin walls. The ability to produce parts with tight tolerances makes plastic injection molding ideal for applications that require precise dimensions.

Conclusion

Plastic injection molding is a versatile and cost-effective manufacturing process used in the e-commerce industry. Its ability to produce high volumes of parts with complex geometries makes it a popular choice for a wide range of applications. By understanding the process, selecting the right material, and leveraging its benefits, e-commerce sellers can effectively utilize plastic injection molding for the production of quality products.