Introduction: What is Injection Molding and How Does it Actually Work?

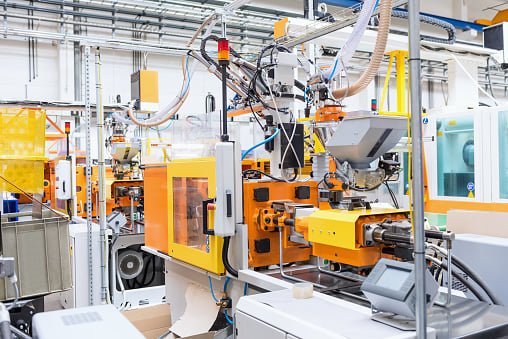

Injection molding is a manufacturing process that turns raw material into a finished product. The process begins with the raw material, which is heated to its melting point, mixed with a liquid binder, and then injected into a mold cavity. The liquid hardens when it cools and forms the desired shape for the finished product.

Injection molding is widely used for producing a wide variety of products, including automotive parts, electronics, and household appliances.

How to Choose the Best Material for Your Product

Choosing the right material for your product can be a difficult decision. However, if you're looking for a durable and long-lasting material, metal is the way to go. Metal is one of the most durable materials on Earth and it's also easy to work with ; There are a variety of metals that you can use for your product, but if you're looking for a durable and long-lasting material, metal is the way to go.

How the Process of Injection Molding Works

Injection molding is a manufacturing process that turns liquid plastic into solid parts. This process starts with a machine that heats and presses the molten plastic into a mold, where it cools and hardens. The machine then opens the mold, and the finished product falls out. The injection molding process is used for making a wide variety of products, such as car bumpers, trays, and toys.

Benefits of Using Injection Molding in Your Production Process

Injection molding is a process used to create plastic parts. This process is often used for making small, inexpensive plastic parts. Injection molding has a number of benefits including

:- The process does not require a lot of skill or experience. Injection molding can be done by any person with a basic understanding of plastic materials and manufacturing processes.

- The process is relatively inexpensive and requires few specialized tools.

- The process is capable of producing high quality parts with very intricate shapes, designs, and textures.

- Parts can be created in a variety of colors using different dyes or pigments to produce the desired color for the part.

If you want to learn more about us, please just contact us and leave your questions below.