Introduction: What is Plastic Molding and How Does It Work?

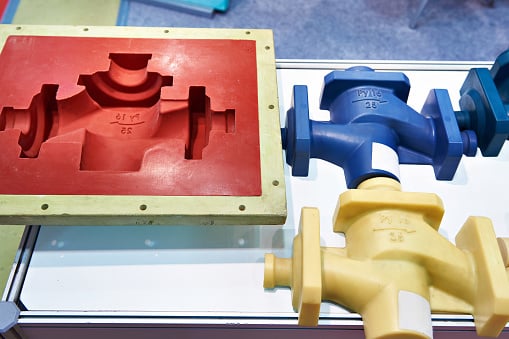

Plastic molding is a process used to create objects from plastic materials. It involves heating plastic materials to a molten state and then injecting them into a mold, where they cool and take the shape of the desired object. Plastic molding is used in a wide variety of industries, from automotive to consumer products, and it is an essential part of modern manufacturing. This article will provide an overview of the process and explain how it works.

The Benefits of Using Plastic Molding for Your Business

Plastic molding is an effective and efficient way to manufacture products for businesses of all sizes. It offers a number of advantages, such as low cost, high precision, and quick turnaround times. Plastic molding also allows for the production of complex shapes and intricate details that would otherwise be difficult or impossible to create. The use of plastic molding can help businesses save time, money, and resources while producing high-quality products.

What Are The Types Of Plastic Used In Plastic Molding?

Plastic molding is a process used to create a variety of products from plastic. Different types of plastics are used in this process, each with its own unique characteristics and benefits. Some of the most common types include ABS, Polypropylene, Polyethylene, and Acrylonitrile Butadiene Styrene (ABS). Each type has its own advantages and disadvantages when it comes to plastic molding. Understanding the different types of plastics can help you make an informed decision when selecting the right material for your project.

How To Choose The Right Type Of Plastic For Your Project?

Choosing the right type of plastic for your project can be a daunting task. With a variety of options available, it is important to consider your needs, budget and application when making this decision. Fortunately, there are several resources available to help you determine which type of plastic is best for your project. From understanding the different types of plastics to learning about their properties and applications, this guide will provide you with the information you need to make an informed decision.

The Process & Cost Involved in Manufacturing a Product Using Injection Moulds

Injection moulding is a popular manufacturing process used to produce a variety of products. It involves injecting molten plastic into a mould to form the desired shape and size. The process is cost effective and time efficient, making it ideal for mass production of identical parts. The cost involved in injection moulding depends on the complexity of the product and the number of moulds required for its production. Additionally, other factors such as material type, cycle time and labour costs also affect the total cost.

Contact the REX Team right away for more details on our services.